DSI ExConTec

POWER AND TENSION ANALYSIS SOFTWARE

More than an analysis tool, the DSI Expanded Conveyor Technology reflects a philosophy. Our comprehensive approach takes the conventional conveyor technology beyond the currently perceived limits. Utilizing derived load equivalents, we are the first to address and predict the extra fexural and shear resistances along vertical and horizontal curves. Our analysis models and software incorporate added features including the “Engineer’s Discretionary Factors” – an allowance for incorporating the results of the field testing or simply our client’s philosophy.

SPECIAL FEATURES OF THE DSI ExConTec

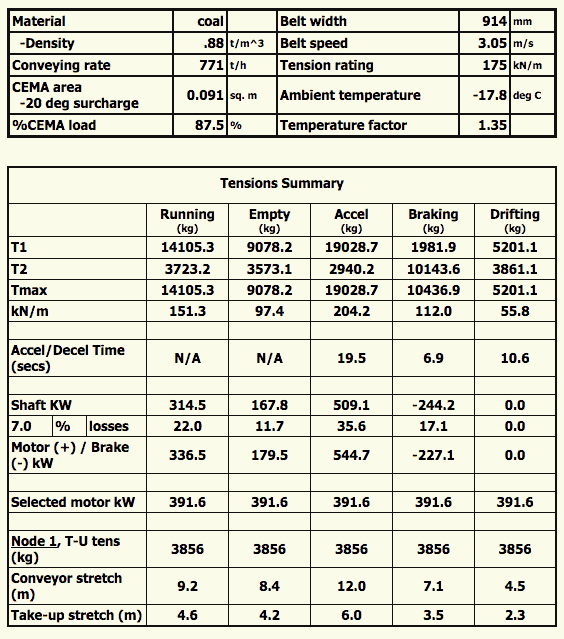

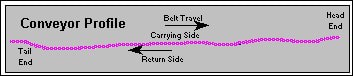

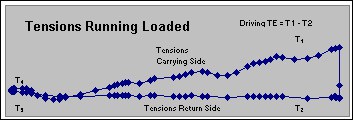

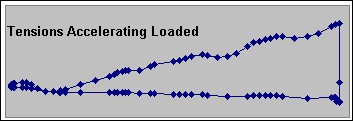

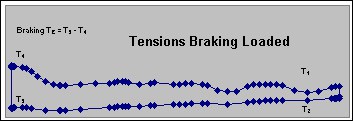

COMPLETE TENSION AND POWER ANALYSIS Each run produces a complete tension and power analysis under steady state, starting and stopping conditions. Stopping is by braking and by drifting. Starting and stopping analyses utilizes rigid body dynamics. Complex conveyors are easily analyzed, including horizontal, vertical and compound curves, as well as multiple loading points and two-way conveyors.

GRAPHICAL DISPLAY OF CHANGING LOAD CONDITIONS Sequential runs, using macros, allow real time analysis and graphical display of changing load conditions including load-on, trailing-off and any discontinuity of material flow. This feature allows us to quickly spot the aggravations of flow discontinuities.

ACCOUNTS FOR ALL BELT LINE RESISTANCES Virtual material loads, or “load equivalents” are used to account for belt line resistances associated with the curving profile or plan of the conveyor line. These (previously unaccounted for) resistances become significant at horizontal curves where the effect is always increased resistance.

UTILIZES YEARS OF REAL WORLD EXPERIENCE CEMA “Ky”, “flex” and “shear” resistance factors are supplemented with additional influences that reflect DSI experience and philosophy.

AIDS IN THE RESOLUTION OF SLACK BELT ISSUES In the analysis, belt tension becomes negative (compressive) when it drops below zero. This, though not realistic (as belt becomes slack), allows continued analysis indicating the tension increase required to correct the slack belt problem.

EASILY ADAPTABLE BY QUALIFIED ENGINEER An input section entitled “Discretion by Responsible Engineer” offers the user an opportunity to affect the analysis by use of adjustment factors on the “Ky” and “Kx” values and on the terminal resistances. These factors can be used to alter the results according to known characteristics of the conveyors being analyzed, to reflect the user’s design philosophy or to achieve matching of field monitored data.