THE EXPANDED CONVEYOR TECHNOLOGY

In 1979, a “High-angle conveyor study” was funded by the U.S. Department of the Interior, Bureau of Mines and executed by Dravo Corp. The target applications in openpit mining, required high-volume conveying rates of the coarsest materials along the most direct steeply inclined paths (along the pit wall.) This precluded the C-shaped loop belt profile but not the principles of operation. In depth research sought to unify the sandwich belt technology with the conventional conveyor technology, thus expanding the conventional conveyor technology and ensuring that none of the equipment is subject to adverse loading conditions beyond its intended use.

A study of all methods of steep-angle conveying found the sandwich belt approach to be the most promising but also the least understood technologically. Basic research of sandwich belt conveyors began with the study “Cover Belts of the 1950s” and continued with study of all developments and variations through the 1960s and 1970s. Like the 1958 Rasper review we sought characteristics and features that produced success in order to create a basis, complying to our findings, that would ensure success. That rationalization is revealed in detail in the 1982 article “Evolution of sandwich belt high-angle conveyors” by Dos Santos and Frizzell. The basis to ensure success is complete adherence to the rules of conventional conveyor technology while ensuring complete continuity of hugging on the material regardless of the conveying rate (from empty, through overload, with continuous and discontinuous material flow) and material size distribution. The former will ensure long life of the belting, components and the equipment while the latter ensures frictional development of the material within the sandwich and precludes any material slide-back.

Though the loop belt displayed the key characteristics, it failed to offer the desired profile and did not adhere to all design rules of conventional conveyors. Rather, it featured exceptions of convenience. The latter are to the detriment of the system.

SANDWICH BELT HIGH ANGLE CONVEYORS - SNAKE OR GPS

“Evolution of sandwich belt high-angle conveyors”, has expanded the conventional conveyor technology into sandwich belt conveyors ensuring that such systems will have all of the operating and maintenance characteristics of conventional conveyors and will be as widely applicable. With emphasis on the technology rather than particular manifestation that writing goes on to propose some five different sandwich belt conveying methods that when executed according to the guidelines established will result in success. Since the 1980s, two of the variations have achieved long term commercial success with numerous units in operation around the world. The first variation, the chosen preferred system of the Bureau of Mines study is the Snake Sandwich High Angle Conveyor. The second variation, the mechanically pressed sandwich achieved success as the HAC and the GPS. Whereas the snake principle governs the overall profile of both variations, the Snake or GPS options affect only the straight high angle portion of the profile. So, all successful sandwich belt systems have the “heart of a snake”.

Purely Snake

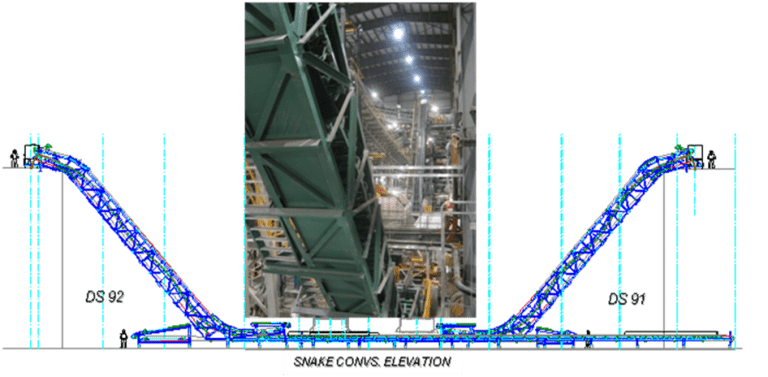

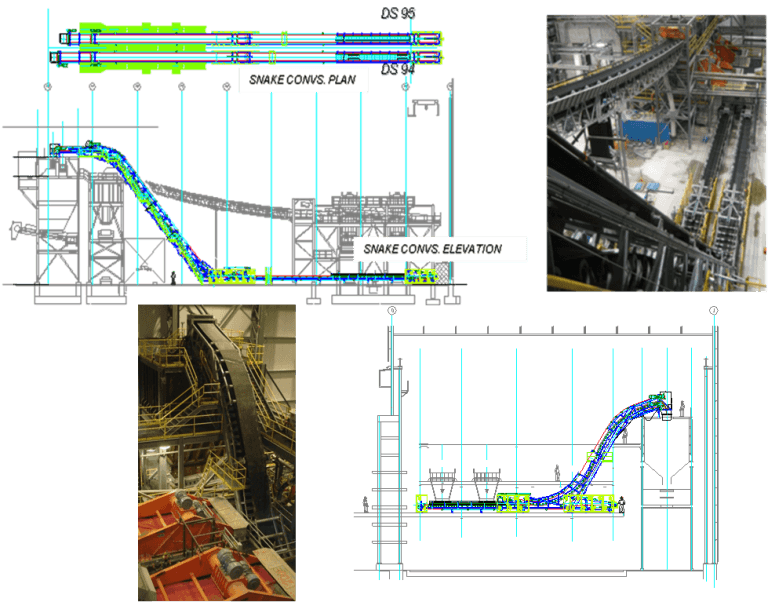

The Snake Sandwich belt high angle conveyor was first introduced to the industry at “Mining Equipment International”, April 1982. The Snake system uses all (and only) conventional conveyor components and equipment and smooth surfaced belts that are continuously cleaned by scraping. Hugging pressure on the conveyed material is entirely imparted by a radial pressure which is induced by the inherent belt tension on an engineered curving profile.

GPS – Gently Pressed Sandwich

The GPS option applies only to the straight high angle portion of the profile. Rather than alternating convex curves, hugging pressure is applied onto the top belt by closely spaced, fully equalized pressing rolls.

Extended C and S-shaped profiles are facilitated by a multitude of profile curves with inflection zones between adjacent curves, as in the purely snake system, or by the GPS system along the straight portion of the profile. To meet the industry requirements, about half of the Sandwich belt units will be of simple profile as shown in the basic profiles.

These principles have been demonstrated successfully in nearly 200 installations worldwide. Many of these installations, which are of loop belt systems, Many more Sandwich belt systems have been built for the low tonnage and duties of municipal waste and chemical sludge handling and other industries. Though these smaller systems are admirable, they are not suitable for the high volume requirements of open pit mining, transfer yard and dock and power plant applications. Despite the numerous successes, Sandwich belt conveyor systems have not been generally embraced as main stream conveyor technology rather these have been viewed as a specialized technology. The DSI Sandwich belts represent an expansion of the mainstream conventional conveyor technology, subject to all pre-established rules of good conveyor design. This will ensure long life of the equipment and belts, and low operating and maintenance costs. Applicability is as wide ranging as for conventional conveyors. Mainstreaming of the sandwich belt high angle conveyor technology is long overdue and this will come with wider and routine use.

THE COST/VALUE OF HIGH ANGLE CONVEYING

The favorable economics of materials haulage by belt conveyors has long been acknowledged. The economics become even more favorable with increased volumetric rates and lifts. The superior reliability and availability of belt conveyors along with lower operating and maintenance costs are factors generally acknowledged. These favorable characteristics have also been demonstrated at numerous installations of sandwich belt high-angle conveyors. Indeed, such systems, in compliance with the expanded conveyor technology, have equaled or outperformed the conventional conveyors at the same job site subject to the same or similar duty.

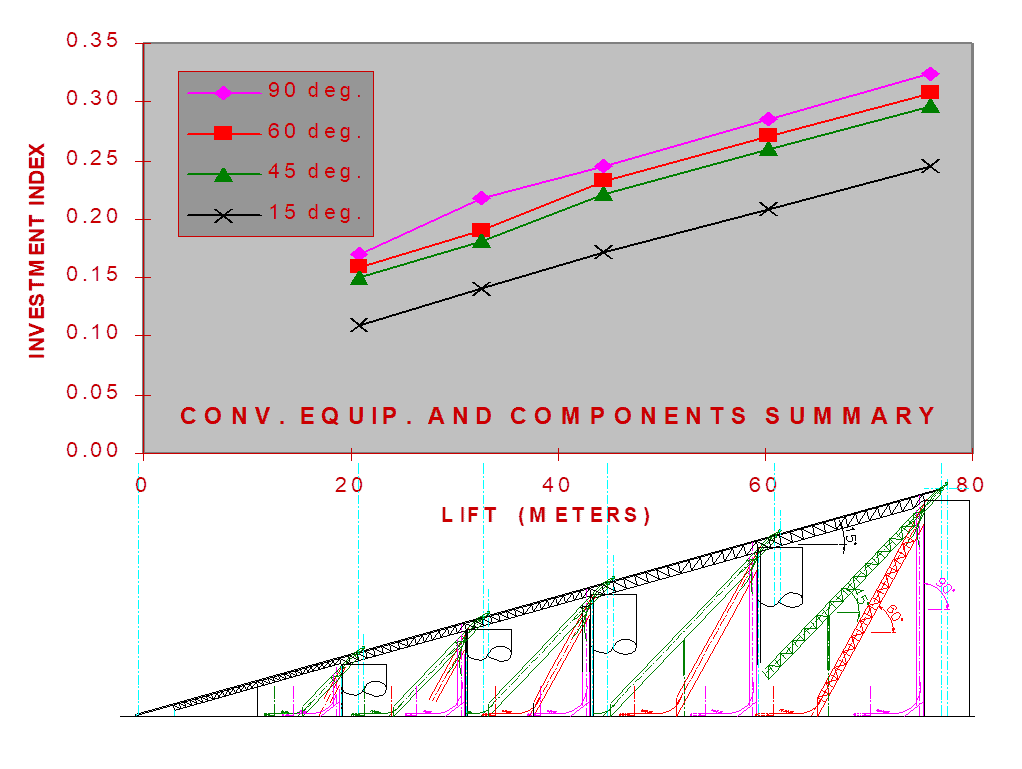

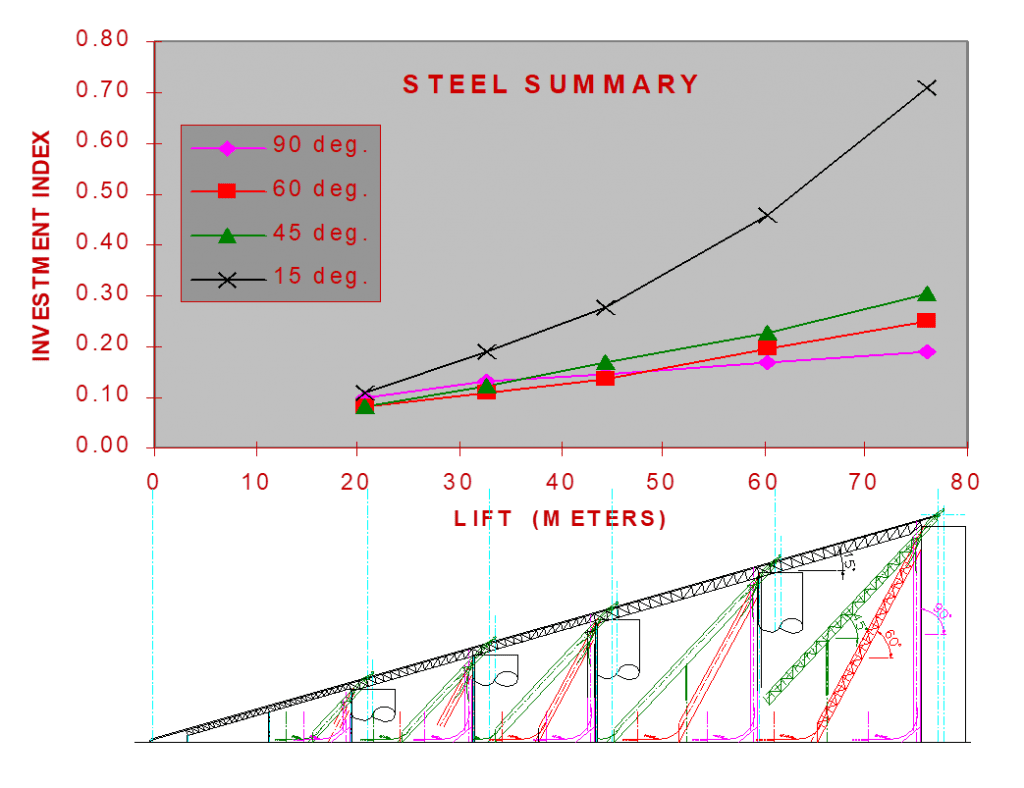

This article will not compare the economics of belt conveying against other haulage methods, nor will it compare the operational and maintenance characteristics and costs of conventional and sandwich belt conveyors, since these are demonstrated to be equal in numerous applications. Instead, a comparison of the investment costs (engineering and supply) of four conveying paths to silos of various heights will be given. The four conveying paths, shown below are by a conventional conveyor and three variations of the Snake Sandwich belt conveyors as follows:

- Conventional conveyor at 15° slope.

- Snake at 45° slope.

- Snake at 60° slope.

- Snake at 90° vertical.

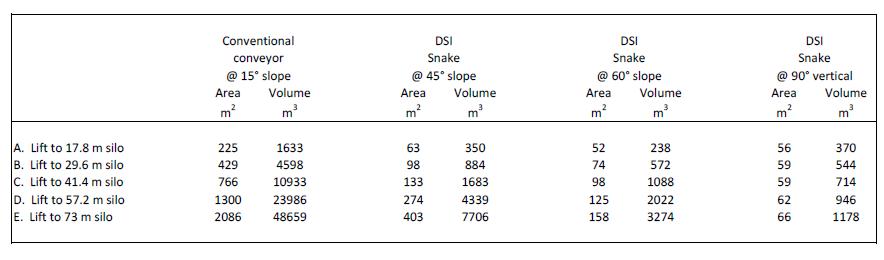

The silo heights vary from 17.8 to 73 m (58.4 ft to 239.5 ft) with the system lifts being an additional 3 m (10 ft). In addition to total investment costs, cost breakdowns will be examined. Such breakdowns reveal economic sensitivity and imply operating and maintenance characteristics. Some important non-cost factors will also be analyzed.

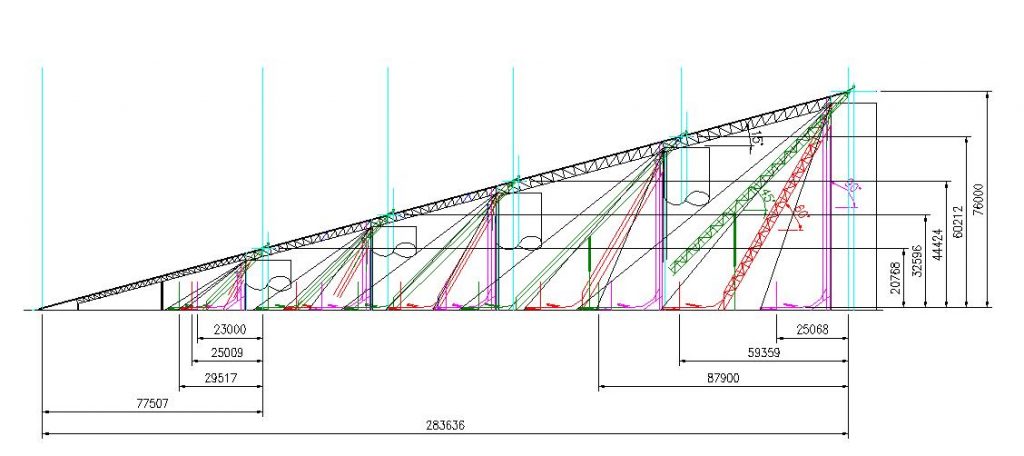

The illustration above shows the configurations of the conventional and high-angle conveyor elevating options to silos of increasing height. Overall dimensions illustrate the significant differences in the foot print required for the alternate profiles.

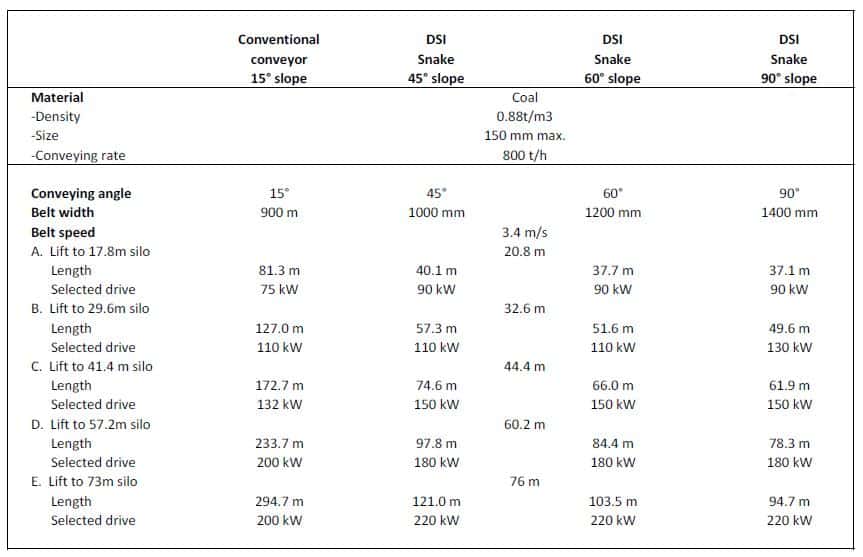

The table below summarizes the technical basis for the design and estimating of the various elevating options.

BELT WIDTHS

It is important to note that increasing belt width is required with increasing angle. Compared to the conventional troughed belt conveyor, a Sandwich Belt high-angle conveyor carries a lesser material cross-section for a given belt width, having a larger material-free edge distance and ample margin against overload. Furthermore, the material cross section at a Sandwich conveyor is de-rated with increasing high angle. Accordingly, the vertical Sandwich Belt conveyor requires the widest belts (1,400 mm or 55.2 in.), components and structure for the same coal throughput rate and belt speed. The cost consequence is seen at the conveyor equipment and components summary. However, it does result in heavier, possibly more durable equipment.

DRIVE POWER

The drive power chosen differs from the calculated required as we selected the next commonly available motor size and drive components. This is further aggravated by choosing equal drive units at the top and bottom belts of the DSI Snakes. The results in investment costs appear as less than smooth curves at the conveyor equipment and components summary.

CONVEYING ANGLE AND SAFETY AGAINST MATERIAL SLIDEBACK

Safety against material slide-back is an important factor in any materials elevating system. Such a consideration might lead the conservative to erroneously choose the conventional conveyor as the safe solution. In fact, there are many documented cases of conventional slope conveyors at inclines of 15°, 16° and 17° that experience frequent material slide-back, especially when excessive moisture or frost are involved. The author knows of no material slide-back at any of the more than 100 Sandwich belt conveyors designed in compliance with the “Expanded Conveyor Technology”. The safety factor against slide-back is well known at a Sandwich Belt conveyor system because it is chosen when choosing the induced for applied hugging pressure. Indeed, such a selection does not exist for conventional slope conveyors and an equivalent safety factor against material slide-back would limit conventional conveying angles to less than 12°, even with coal and crushed rock.

As a consequence of experiencing material slide-back with 16° and 17° conveyors, a study at a major coal company objectively determined and resolved that their conventional conveyor slopes should never exceed 12°. Their next elevating conveyor project was designed and built in compliance with this new criteria. The cost impact on this project was so high as to immediately cause reconsideration of the conservative criteria. It was then resolved that their conventional conveyor slopes should never exceed 14°. Such cost driven compromises are unnecessary with the sandwich belt conveyors that are pursuant to the described development.

STRUCTURAL OPTIMIZATION

For the sake of a fair comparison it was important to structurally optimize the alternate elevating systems, especially the conventional 15° slope conveyor. It is well known that structural bents and towers become massive and expensive with height. In order to minimize the mass and cost of structural steel, the structural spans with height must be increased to minimize the number of very high and massive bents. In this case truss spans were chosen, beginning from grade, of 30.5 m, 45.7 m and 61 m (100 ft, 150 ft and 200 ft) for the first, second and third pairs of trusses. Having established approximate structural optimization for the conventional 15° conveyor, silo wall locations at the bents were chosen.

BASIS FOR AND PRESENTATION OF COSTS AND PRICING

A fair cost comparison must be in compliance with a single and uniform design and pricing philosophy. Every buyer and every seller knows that the same inquiry and specification will result in, at times, widely varying price offers by various manufacturers. Even the same manufacturer’s offer will vary depending on the competitive situation and his desire for the work (i.e. having a high or low current work load.) Though our pricing herein is in compliance with the uniform design and pricing philosophy of Dos Santos International, all pricing of comparison is presented in the form of an index. Any reader can then normalize this cost comparison according to their own buying and/or selling experiences and policies.

COST COMPARISON

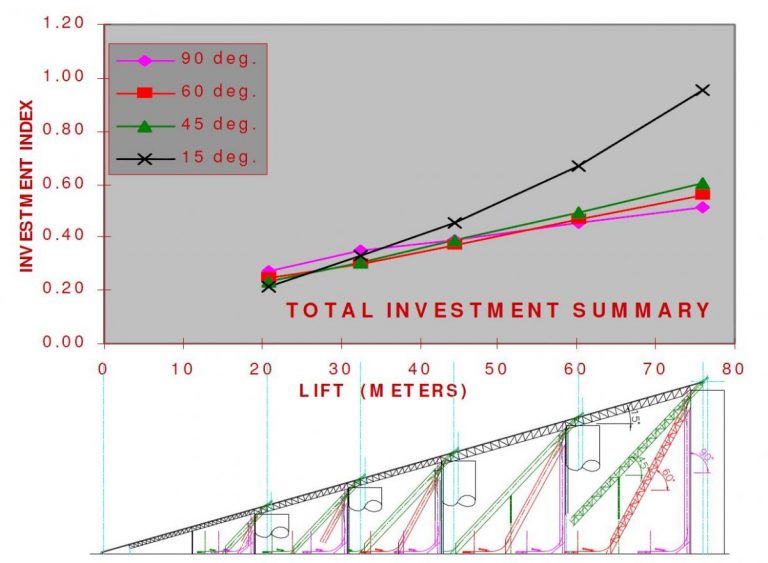

The above figure graphs the investment cost (engineering and supply) for the four elevating systems as a function of increasing silo height. This does not include civil, foundations or installation. It is not surprising that the conventional 15° slope conveyor proves least costly when elevating to the lowest silo of 17.8 m (58.4 ft) height. However, the cost of the conventional conveyor system increases exponentially with height. Beyond approximately 33 m (108 ft) of lift it becomes the most expensive solution. At 76 m (250 ft) of lift its cost exceeds the sandwich belt solutions by a range of 60 percent to 88 percent. But, the variation in investment cost for the sandwich belt solutions is approximately linear with silo height and quite modest with regard to each other. At the lowest silo height, a sandwich belt system of 45° slope has a 0.23 investment index compared to 0.24 (4 percent higher) for a 60° slope and 0.27 (17 percent higher) for the vertical unit. At the highest silo, the vertical sandwich belt system has the lowest investment index at 0.51 compared to 0.56 (10 percent higher) for the 60° slope and 0.60 (18 percent higher) for the 45° slope.

The figures below show the relative make-up of the investment costs. The first figure graphs the investment in conveyor equipment and components. This includes belting, idlers, pulleys, drives, switches etc. It can be seen that the investments increase linearly with height. Furthermore, the conventional 15° conveyor has always the lowest investment in conveyor equipment and components while the vertical sandwich belt conveyor is always the highest. This is due to the required wider belts and corresponding equipment. The great cost differentials between the conventional 15⁰ slope conveyor and the sandwich belt conveyors are owing to the great difference in structural steel requirements, as illustrated in the second figure. The steel in this case includes all truss spans, bents, terminal framing, covers, access walkways and stairways, chutes, skirts etc.

IMPORTANT INDIRECT COST FACTORS

It is worth noting some important indirect cost factors for comparison. The table above shows a comparison of displaced projected (ground) areas, spatial volumes and perimeter area, above grade, for the different elevating systems. Significant indirect costs can be associated with each of these quantities. For the displaced ground area there is a real estate cost. For the spatial volume and perimeter area above grade there is a very real cost when the conveying system is part of a housed or covered facility. The cost of the building or covering is directly related to the displaced spatial volume and exposed surface area. In the case of heated facilities, required in frigid climates, heat is lost through the exposed surface area in direct proportion to that area. Also important is the minimal environmental footprint of the high angle conveyor solutions.

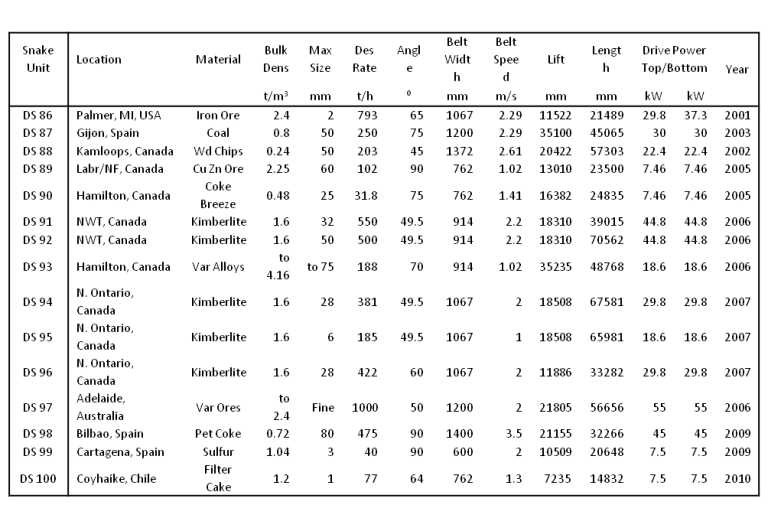

LATEST SANDWICH BELT HIGH ANGLE CONVEYORS, EXAMPLES OF INDIRECT COST

This table summarizes some of the latest Sandwich Belt high-angle conveyor systems. Each has its unique project account and reason why it was the best solution. Four projects which are examples of the significant indirect costs are examined.

SNAP LAKE AND VICTOR PROJECTS

The indirect costs are real and significant. Such costs motivated DeBeers Canada, more than 25 years ago, to incorporate Sandwich belt high-angle conveyors into the planning of the recovery facilities of their two premier diamond mines, at Snap Lake, Northwest Territories, and at Victor Project, Northern Ontario, Canada.

The illustration below shows how the two Snake Conveyors define the size of the recovery facilities, each conveying to the opposite side of the building. Conversely one can extrapolate how much larger the building would be if conventional conveying angles were used to achieve the required material lifts to the various crushing and screening stages of the recovery functions. Located in Canada’s Northwest Territories, near Yellow knife the facilities are routinely subjected, in winter, to frigid temperatures below minus 40⁰. This requires heating the large facilities throughout the winter at a great expense in natural gas. That expense is minimized as is the environmental footprint because of the shorter elevating distances possible with high angle conveyors that are suitable for the handling requirements.

The story at the DeBeers Victor project is similar and represents a continuation of confidence in the Sandwich Belt high angle conveying systems. The Victor project is located in Northern Ontario, west of James Bay in the region of Attawapiskat. Like Snap Lake, the climate is frigid in the winter and the facilities must be continuously heated. The arrangement at Victor is somewhat different than Snap Lake with twin Snake Conveyors (one for coarse pebble ore and the other for granular ore) travelling in the same direction from the secondary screen, at one end of the building, to the next screening and crushing stages at the other end. A third snake unit, running in the perpendicular direction, transfers coarse pebble ore back to a crusher feeding conveyor. This unit in affect defines the width of the building.

The building is shorter and narrower because of the high angle conveyors, minimizing the environmental foot print, the building costs and the fuel costs to heat the facilities in winter.

The indirect costs are also real and significant at the Port of Adelaide, NSW, Australia. There the savings are in dock costs. The photo above shows the Snake Ship Loader maneuvering easily within a narrow dock space. The height required to load the Panamax class ships could not be accomplished with the low angle of the conventional ship loaders. Extensive additional dock construction would be required with the conventional systems.

WIDEST BELTS, HIGHEST VOLUMETRIC RATE

Most interesting is the latest commercial system as it dramatizes the high angle advantage from a practical, environmental and cost standpoint.

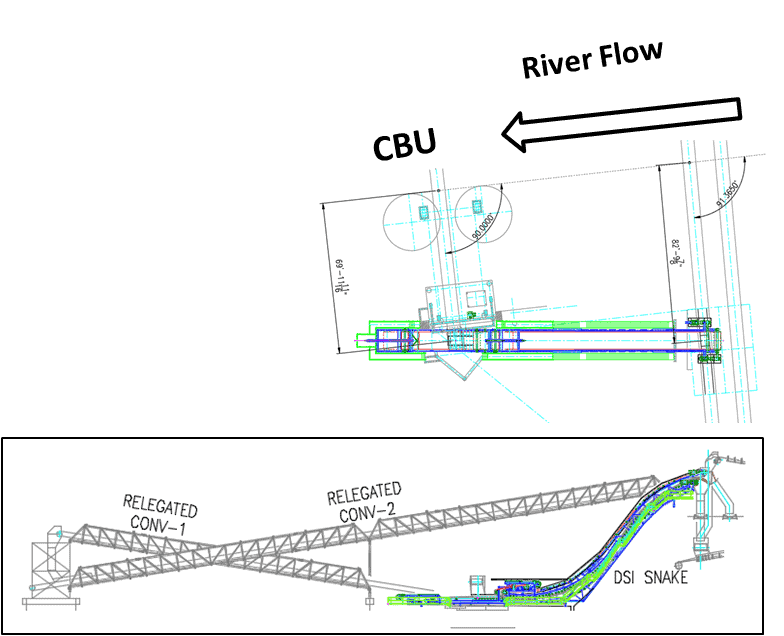

The major expansion of a lower Mississippi River transfer terminal resulted in a short conveying path from the down river CBU (continuous barge unloader) to a new transfer complex over parallel yard conveyors that can alternately direct the coal flow to the storage yard or to ship loading. This most direct path subtends an incline angle that far exceeds the capability of any conventional open troughed belt conveyor. The reflexive solution was to use two conventional open flights in a switch-back arrangement. A specified 9° maximum incline limitation and the location over water made this a costly proposition. The large (environmental footprint was also negative.

Because of the long relationship with Dos Santos International, terminal personnel knew there was a better solution, a DSI Snake Sandwich High Angle Conveyor. At 3629 t/h (4536 cu-m/h) of coal this is the highest volumetric rate to date for a Dos Santos Sandwich Belt high angle conveyor.

The DSI Snake was ordered in April of 2014. The DSI Snake profile is depicted here, along with the alternate conventional conveyor solution for contrast. At 2438 mm of belt width this is the widest Dos Santos Sandwich belt unit

WHICH IS THE BEST ANGLE?

The best elevating profile depends largely on site and functional requirements. In general, the best solution is the most direct path from loading point A to discharge point B. The present study however reveals economic comparisons that would prompt a combination conventional conveyor along the ground to an elevating sandwich belt conveyor, even when ample space exists for a conventional conveyor solution. This can be a sandwich belt conveyor with a long approaching bottom belt. In general, loading point A and discharge point B will be located for the best use of space. The total investment comparison reveals large differences, at the very high lifts, between the conventional and the sandwich belt conveyors but not among the Sandwich Belt systems. At the highest lift, a 60° DSI Snake profile has approximately 10 percent higher investment than the 90° (vertical) DSI Snake. A 45° profile has approximately 18 percent higher investment.

Operational considerations might warrant the higher investment in a 60° system, or even a 45° system. Such considerations are system clean-up and system access.

Sandwich belt systems at any angle can be designed to greatly limit any spillage. Minor material carry back can occur due to none perfect belt scraping and even the occasional leakage, due to poor belt alignment and other aggravations. The magnitude of the accumulation is far less important than its nature and consequence. At a vertical system such carry back does not have a clear path away from the equipment and tends to accumulate progressively on the rolling equipment. Periodic cleanup is required, typically by high pressure wash-down. Wash-down water at the outer parts of the wing rolls has contaminated the bearings and caused frequent premature bearing failures requiring high rates of roll replacement. No such phenomenon has occurred at sandwich belt conveyors of any incline less than vertical. Any carry back or fugitive material escape tends to fall away clear of the rolling equipment and build up is not progressive towards the bottom.

Access to the equipment is important in any case. Many specifications require access by stairway (vertical ladders are not allowed). The maximum stairway slope, according to architectural standards, is 50°. At higher angles step ladders (51° to 70°) or ladders (71° to 90°) must be used, with safety lines or safety cages and landings. The cost of stair towers can sometimes approach the cost of the sandwich conveyor systems.

In view of the modest premium and consideration (material carry back), it is this writer’s opinion that the 60° DSI Sandwich solution with access by ladders and landings will prove very economical and most reliable. Furthermore, if a stairway is required then the additional premium may be warranted making the preferred conveying angle less than 50°.

Many cases of limited space will warrant vertical systems. It is not our intent to discourage these as the cited problems can be resolved by conscientious design and clean-up procedure

CONCLUSION

Complete rationalization of the Sandwich Belt conveyor technology in the conventional conveyor technology was achieved in the period 1979 to 1982. Many successful Sandwich Belt steep and vertical conveyors have been built in compliance with that rationalization and have demonstrated the performance characteristics of conventional conveyors. The DSI Sandwich Belt High Angle Conveyor is the only high volume Sandwich Belt system to utilize all conventional conveyor equipment and componentry. Material hugging pressure is induced by exploiting the inherent belt tensions on an engineered alternately curving (snaking) profile or applied by fully equalized, close spaced pressing tolls along the straight profile. An investment comparison shows great savings when conveying to high silos with DSI Sandwich Belt conveyors at various angles from 45° to 90° (vertical). To date, sandwich belt conveyors have not been widely recognized as mainstream technology despite the many successful systems and the demonstrated economies. There is no basis for reluctance in the wide use of sandwich belt conveyor systems. Such systems should be embraced as mainstream technology and exploited to lower the costs of silo loading and other applications.

This article has focused on the cost of elevating materials to silos. High angle conveying is equally advantageous in elevating to other covered storage systems such as storage barns and domes. Dome type structures for covered storage have gained prominence and use. The DSI Snake profile is ideal for continuously elevating materials to the top of such domes sharing a compatible curving geometry. Enroute to discharge, at the top of the Dome, a DSI Snake system will impart a gentle distribution of structural loads onto the Dome structure. The combination will be an aesthetically pleasing, uncluttered system.