The Sandwich Belt high angle conveyor technology was developed by Joe Dos Santos between 1979 and 1981 while at Dravo Corporation, Pittsburgh, PA, USA. The technology basis for the commercial success was revealed in the landmark writing “The Evolution of Sandwich Belt High Angle Conveyors” by Dos Santos and Frizzell, first published in 1982. Commercial success awaited demonstration of the principles followed by the first sale. This happened in 1983, forty years ago.

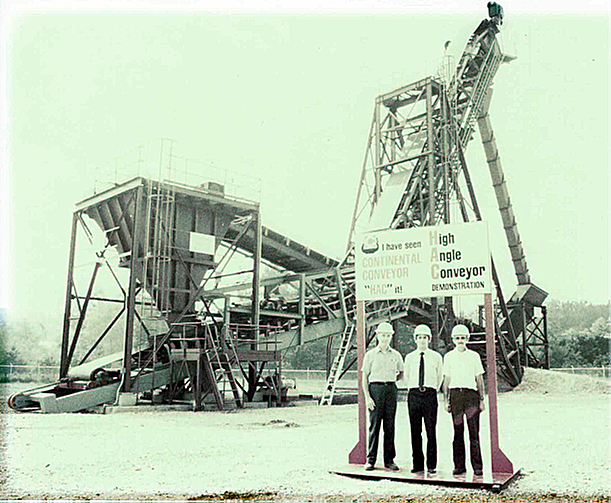

Joe Dos Santos joined Continental Conveyor of Winfield AL, USA in July of 1982 with the mission of bringing his writings to reality. After only a short planning period, engineering began on a large-scale prototype Sandwich Belt high angle conveyor that would convincingly demonstrate the principles to the industry and academia. For this purpose, the prototype was of large scale and incorporated much versatility to facilitate extensive testing. It featured 60-inch-wide belts, variable belt speeds to 6 meters/second (1200 feet/minute), variable incline from 30 degrees to 60 degrees, a precise power monitoring system and much more.

By July 1983, this prototype was engineered, manufactured and constructed, ready for start-up and operation. On the very first day of start-up, the Sandwich Belt prototype conveyed coal

successfully at the incline angles of 30 degrees, 45 degrees then 60 degrees. Following the July 1983 start-up, the system underwent a full year of testing and demonstrations with widely varying materials from light, friable woodchips and grains to heavy, coarse primary crushed ores.

The first commercial sale was made before year-end 1983 marking the start of commercialization. After a demonstration of Powder River coal running at 2000 S-tons/hour, at 60 degrees incline, Triton Coal Company purchased the first commercial unit to elevate 2000 S-tons/hour of coal at 60 degrees to train load-out silos at their Buckskin Mine, Gillette, WY, USA.

In the development effort, Joe Dos Santos was fortunate to have the full time dedication of Tommie Robertson and Jim Cox. Tommie handled the design, drawing duties and more. Jim handled all electrics; power, distribution and controls. Additionally, during this time, Tom Hubbert, now DSI vice president of engineering, assisted in these efforts as an Auburn undergraduate student. Tom was a co-op at Continental Conveyor under the direction of Joe Dos Santos.

Forty years later, the Dos Santos Sandwich Belt high angle conveyor technology continues to be implemented throughout the world in hundreds of applications from energy and power, mining, pulp and paper, port and harbor, tunneling, recycling, cement, wastewater treatment and steel-making.

“THEN, 1983” – (left to right) Jim Cox, Joe Dos Santos and Tommie Robertson with large-scale prototype in the background, Winfield, AL USA.

“NOW, 2023” – (left to right) Joe Dos Santos and Tom Hubbert, at the DSI Marietta, GA, USA office. As a young co-op student, Tom was part of the HAC development team.