Dos Santos International is pleased to announce the award of a patent and first order for the newest development in sandwich belt conveying technology. The DSI Adder Snake (US Patent number 9,815,627) was awarded on November 14, 2017.

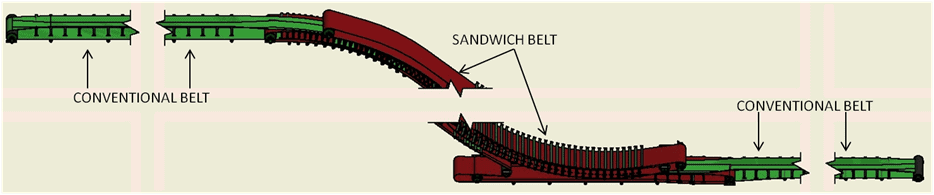

Sandwich Belt high angle conveyors have long been known as the best solution for tight spaces where a steep lift is required to maintain a small footprint. However, applications are also quite common in which a large footprint is available, but a high angle is needed in just a small portion of the conveyor path. Because a Sandwich Belt system uses a wider belt to achieve the same conveying rate as a conventional conveyor at the same speed, in an application such as that described above, the question can be asked: Should you extend the tail of the Sandwich Belt, or should you break up the path into two separate conveyors, in which a narrow conventional conveyor discharges on to the wider Sandwich Belt system?

For instance, a tripper may travel horizontally along the length of a dock to feed a perpendicular shiploader. In cases where the shiploader is at a considerably higher elevation than the dock conveyor, a standard tripper would require that the dock conveyor and the dock be much longer than otherwise necessary, as its uplift would extend quite far back from its discharge pulley. Historically, the solution in this case would be to design a much lower-lift tripper, which would then feed on to a Sandwich Belt high angle conveyor. While this is a perfectly viable solution, which has been executed in the past as shown in Figure 2, it would be preferable to eliminate the conventional-to-Sandwich transfer if possible.

While this is a perfectly viable solution, which has been executed in the past as shown in Figure 2, it would be preferable to eliminate the conventional-to-Sandwich transfer if possible.

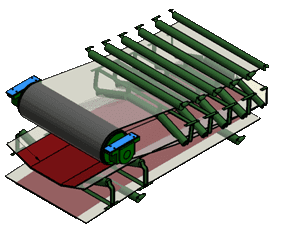

The concept of the DSI Adder Snake, invented by DSI’s vice president, Marc dos Santos, was inspired by a specific application. The DSI Adder Snake swallows a narrower conventional belt, along with its material, into the two wider sandwich belts, allowing the material to enter the sandwich belts with minimal disturbance. It does this without the energy loss and additional equipment required for a standard transfer.

The use of this technology extends to a wide variety of applications, including marine terminals, docks and shiploading.

Dos Santos International is the world’s foremost authority on sandwich belt high angle conveyors, founded and led by the inventor of the system, Joseph Dos Santos. DSI was founded on its extensive worldwide experience in sales, engineering, and construction of bulk materials handling systems and equipment. This has included major contributions that have expanded the range of bulk handling and transport solutions. Most notably advances in sandwich belt high angle conveyors have led to their worldwide utilization. The expertise of DSI spans a wide range of materials handling systems and equipment including high angle conveyors, high powered, high capacity, high lift slope conveyors and long overland conveyors utilizing the very latest technology.