There are many ways to convey bulk materials, and no one knows that better than Dos Santos International. Dos Santos International is the world’s foremost authority on high angle conveyor applications and design of sandwich belt type high angle conveyors. The flagship systems of Dos Santos International are the DSI Sandwich Belt High Angle Conveyors. These systems sandwich materials between two belts with a gentle, yet firm, hugging pressure. Materials can be elevated to the highest of angles (to 90⁰ vertical), through “C” and “S” shaped profiles, and other unique profiles. Not only are the systems versatile, they have proven to be economical, reliable and “green.” The foresight of the Dos Santos International conveyor technology established an environmentally friendly method of conveying bulk materials simply by its advanced design. With increased pressure on the mining industry for environmentally conscience materials handling, DSI has already set the stage for those solutions.

Twenty years ago, “going green” wasn’t quite the popular phrase that it is today. However, that is when Joseph Dos Santos, President of Dos Santos International was presented with a challenge to go green like no other. The challenge was to use the least amount of space possible to process and separate one of Earth’s greatest treasures…diamonds. The picture to the left shows the processing plant of Canada’s first completely underground diamond mine, Snap Lake. Snap Lake was the motivation for the DSI Snake Sandwich Belt Conveyors in the Northwest Territories.

The Snap Lake ore body is a dyke that dips an average of 12-15° from the northwest shore down under the lake. Kimberlite, the diamond bearing ore, is brought to the surface to the processing facility where the diamonds are extracted. Due to the hostile environment, the facilities must be enclosed and heated. A smaller footprint for the plant was determined to be the optimal way to minimize environmental impact and cost. This led to pursuit of the DSI Sandwich Belt High Angle Conveyors because of their designed space saving features. In the process building, the kimberlite must be elevated then

discharged into the various crushing, screening and sorting functions. The original concept was to use a multitude of Sandwich Belt high angle conveyors to minimize the facilities. This was ultimately rationalized to require only two DSI high angle conveyors, which now define the facility’s minimal footprint. These units utilize the DSI Snake Sandwich design where the material hugging is derived from the belt tension along the engineered serpentine path. The DSI Snake Sandwich Belt Conveyor’s ability to convey at any high angle made it idea. The sandwich belt technology imparts a gentle yet firm hugging pressure on the material in the belt sandwich. This allows the precious gems within the kimberlite to be elevated at high angles, gently and without spillage.

The Snap Lake project incorporates two DSI Snakes, each travelling to opposite ends of the building. The units were standardized at 36” belt width to simplify spare parts inventory. Design of the units included provision for future upgrade, from 275 t/h to 524 t/h, merely by increasing the belt speed. By operating at the lower speed until the upgrade is required the Snakes’ optimal energy efficiency is preserved.

The Snap Lake Mine is operated by DeBeers with a commitment to maintain the highest environmental standards. It is the only diamond mine in the Northwest Territories that certified its environmental management systems to the high international standard, ISO 14001 through advanced exploration, construction and pre-operations.

The success of the Snap Lake system then led to the incorporation of DSI Snake Conveyors with confidence into the Victor Project in Northeastern Ontario. This continued success at the Victor Project, Ontario’s first diamond mine, incorporated three operational DSI Snake Sandwich units. Simplification of inventory was further exercised at the Victor Project with all units at 42” belt width. However, tonnage requirements for these units vary from a low of 185 tph at unit 11 to a high of 422 tph at unit 12. For prolonged equipment life and energy conservation, unit 11 is run at a slower speed than the other units.

There can be no finer example of DSI’s ability to exceed all customer requirements than their latest system at the Los Filos gold mining site. In January 2010, DSI completed the start up for an overland conveyor system at Goldcorp’s Los Filos Project. This gold mining project is located in the Nukay mining district of central Guerrero State in southern Mexico,

and promises to be one of the largest open-pit mines in the country.

Los Filos is a heap leach operation. The ore size is reduced at the crushing plant and then it is hauled to the valley where it is stacked on engineered pads. A chemical solution is sprayed onto the ore, which extracts and absorbs the gold as it trickles through the ore. To regulate seepage rate, agglomerate (cement) is mixed into the ore for optimal ore exposure to the solution. Ultimately, the solution is directed to the plant where the gold is precipitated out.

A previous short-lived system conveyed the ore from the crushing plant to the leach pads via a glory hole ore pass and an underground conveyor, through the hill. An agglomeration drum mixed in the agglomerate before final delivery to the leach pads. This conveying system experienced material flow problems right from the start, especially during heavy rains. The sticky ore tended to plug up the ore pass. Geological instability ultimately collapsed the ore pass, putting the transport system out of service only four months into its operation.

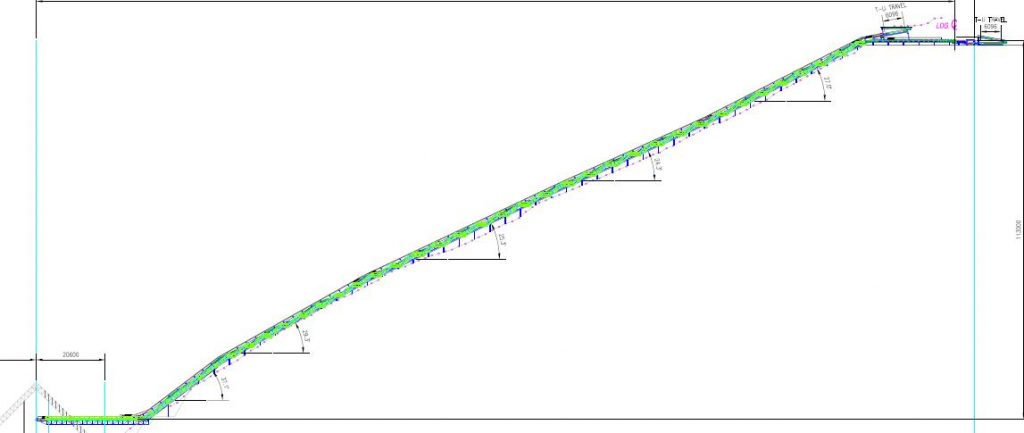

Against this background, M3 Engineering of Tucson, Arizona, USA was tasked with developing an alternate conveying route quickly since all haulage was now by truck and very expensive. The logical, most direct and economical path was over the same hill (rather than under). The path required a down-hill high angle conveyor; thus, Dos Santos International was approached about their DSI Sandwich Belt High Angle Conveyor. Being the best solution, DSI was awarded the contract in March 2009 for a downhill high-angle conveying system which they dubbed the DSI G.P.S. (Gently Pressed Sandwich) High Angle Conveyor. The downhill GPS profile is depicted in the figure to the right.

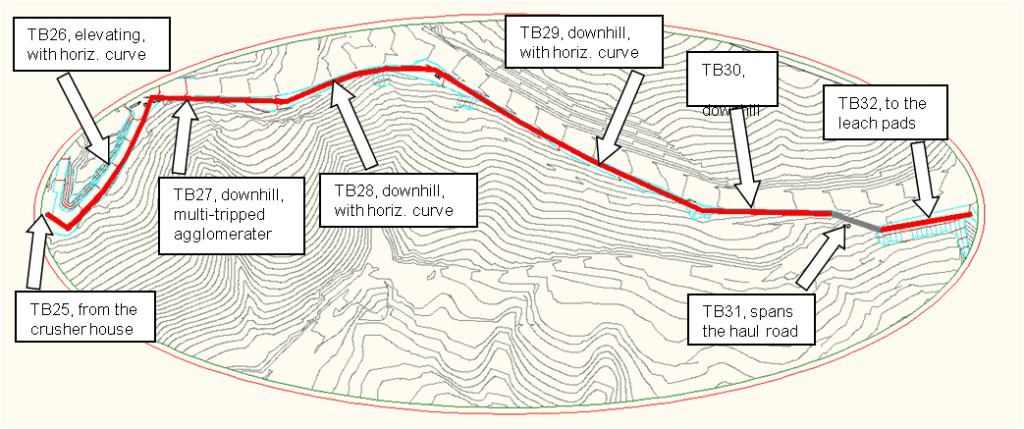

Concerns with geological instability remained, especially along the path of the DSI GPS. Further geological scrutiny led to abandoning this path altogether, thus abandoning the DSI GPS as well. M3 was again tasked with developing an alternate conveying path. This time a conventional conveyor system was developed, following the already developed truck ramps. Dos Santos International again submitted their proposal for the project, now a ten flight overland conveyor system. The project was awarded to DSI on May 19, 2009. The Dos Santos International proposal included two important commitments solely for the customer’s benefit:

- DSI would maximize use of the conveying equipment and structure, already at the mine, from the collapsed and abandoned through-the-hill conveying system.

- The awarded ten-flight system appeared to be a candidate for further rationalization and cost reduction, using horizontal curves to amalgamate successive conveyor flights. The DSI proposal included an amalgamation study as the first order of business.

Both commitments were fulfilled reaping substantial cost savings to the customer. In the former case, the first conveyor flight dubbed, “TB25,” was engineered to use all existing conveyor equipment and structure. Though the arrangement is entirely new, the equipment and support steel are reused from the previous system. The head drive terminal is the only component of TB25 that has new equipment. New steel at the support bents, minor framing, and a new discharge chute make up only a small portion of the total structure. In the latter case, the amalgamation study revealed that six conveyor flights could be reduced to three when joined with horizontal curves. The ten flight system was reduced to the seven flight system that is depicted above. TB26, TB28 and TB29, each with a horizontal curve, are products of the study.

The DSI expertise thus proved particularly advantageous using the horizontal curves to simplify the system and to reduce both capital and operating and maintenance costs. Additionally, the third conveyor flight, TB27 is especially engineered to accomplish the agglomeration by mixing through five intermediate tripped transfers. The enroute agglomeration, conceived by Goldcorp, results in substantial savings by eliminating the need for the additional agglomerating drum.

The overland conveying path is predominantly downhill. While this presents the normal controlled starting and stopping problems, it also presents great savings opportunities. The downhill flights are decisively regenerative. The drive motors, now functioning as generators, feed power back into the grid that powers the other mine equipment. These carefully engineered conveyors are equipped with variable frequency drives to ensure operation at maximum efficiency.

As necessity is the mother of invention, DSI was offered once again the opportunity to provide a solution that turned into an environmental advantage. In June 2015, DSI commissioned its Sandwich Belt High Angle Conveyor for a cement factory in the municipality of Pitimbu, on the coast line of Paraiba, Brazil in 2016. The plant has a capacity of 3000tpd of clinker and 1Mtpa of cement.

The DSI Sandwich Belt features an extended loading zone which is fed by five separate conveyors and chutes and included a material analyzer and magnetic separator to ensure that only the correct feed mixture is transported to the cement making process.

To accommodate protected areas and reduce the plant’s environmental impact, the customer requested a conveyor system with a small footprint. As a result, they chose the DSI Sandwich High Angle Conveyor because of its ability to convey material at higher angles. The DSI Sandwich Conveyor is designed to elevate 720 tph of limestone, iron ore, sand and clay at a 60° angle.

While the sandwiching feature of the DSI Sandwich High Angle conveyor is sufficient to hug and contain most materials, there is the occasional very runny material that tends to move laterally toward the belt edge resulting in minor leakage. Many years ago, Dos Santos discovered that a light moistening of the belt’s surface was sufficient to arrest any lateral movement of such materials. This moistening, at each of the belt’s edges, also has the added benefit of reducing any dust expulsion at the sandwich entrance, where the sandwich is formed. This is the origin of the DSI Wet Brush, now a featured product of the DSI Sandwich Shop.

Because of the widely varied materials that are part of the cement plant raw feed, the first commercial wet brush was incorporated preemptively into the Dos Santos Sandwich Belt High Angle Conveyor at Paraiba.

The DSI Wet Brush uses exact water flow control and measurement that reacts to precise monitoring of the bulk material flow rate. A sonic, broad level sensor at the bulk material feed point, along with a belt speed monitor provide all of the information required to control the wet brush system.

System interlocking maintains a perfectly dry system when there is no bulk material or the feed belt speed is zero. Material flow is measured continuously, and the wet brush automatically adjusts moisture for optimal response.

The Pitimbu project provided DSI with the opportunity to supply their flagship conveyor system that offers not only a smaller footprint, but also improved raw material handling and improved containment of materials.

Dos Santos International is pleased to be on the forefront of offering material handling systems that are not only efficient and cost effective, but can also be included in contributing to the environmentally conscience companies. The DSI conveyor technology in the DSI Sandwich High Angle Conveyor offers options for a smaller footprint, better ways of handling raw material and offering a competent and reliable conveyor system.